- Messages

- 7,908

- Name

- Terry

- Edit My Images

- Yes

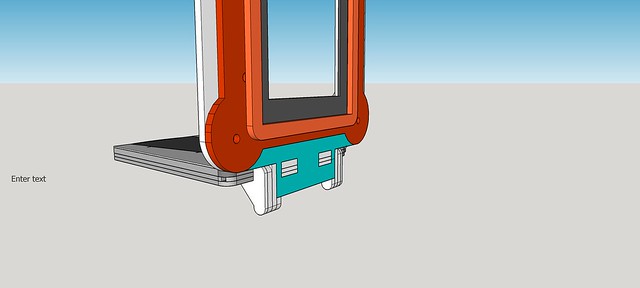

Rather than use a plate on the bottom with a captured thread and rubber surface.It would probably be stronger and certainly far easier to shape and weld on a layer of plastic, to form a camera plate, to fit a Swiss type QR. It would also have none of the thread stripping or thread insert problems and weaknesses. Ant also no tendency to rotate.

I have done it with a shaped piece of thick brown circuit board material. You can also put a strong fine thread into that material, so it could easily be screwed on for belt and braces security.

But it would be easy to satisfy yourself that your acrylic sheet would be easily strong enough. Dovetail clamping is mostly compression and so is incredibly strong in almost any solid material.

If you really must have a screw mount. You could always fix one in the centre of the Swiss type plate you make.

for the rare occasions you might want to mount that way.

I have done it with a shaped piece of thick brown circuit board material. You can also put a strong fine thread into that material, so it could easily be screwed on for belt and braces security.

But it would be easy to satisfy yourself that your acrylic sheet would be easily strong enough. Dovetail clamping is mostly compression and so is incredibly strong in almost any solid material.

If you really must have a screw mount. You could always fix one in the centre of the Swiss type plate you make.

for the rare occasions you might want to mount that way.

Last edited:

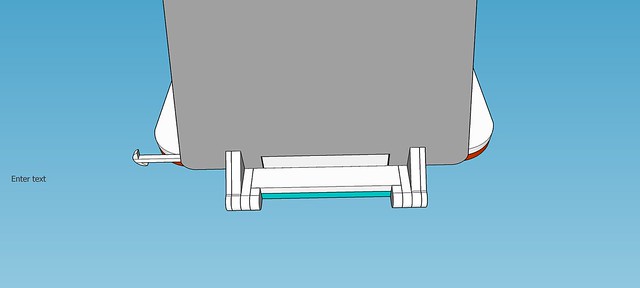

catch

catch catch2

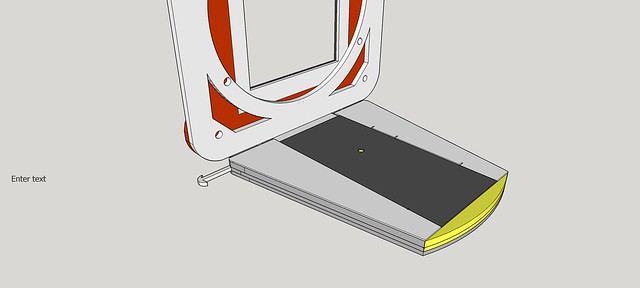

catch2 Too "custom"? ;0)

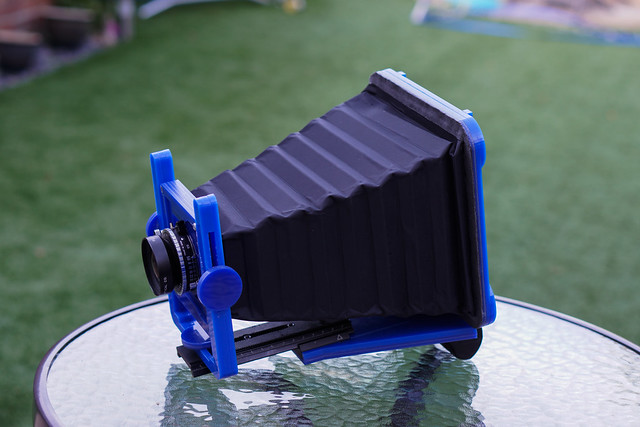

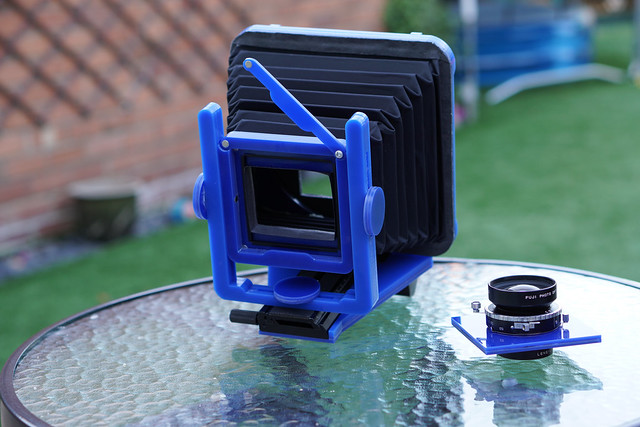

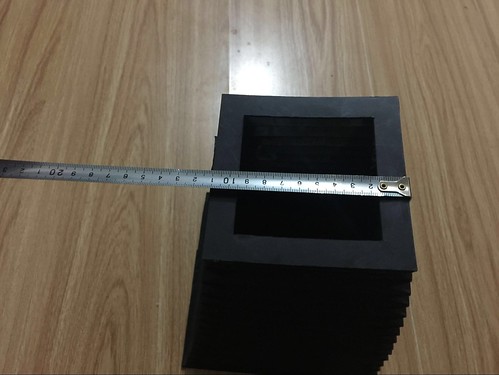

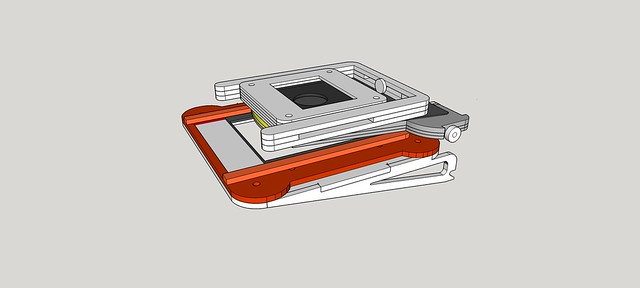

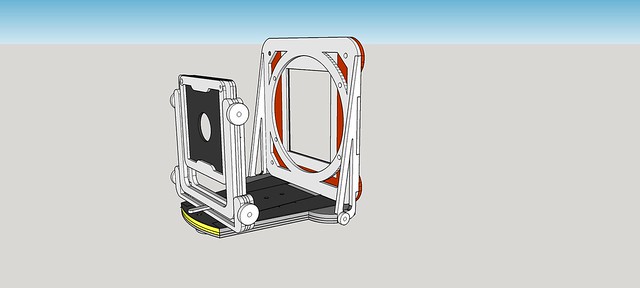

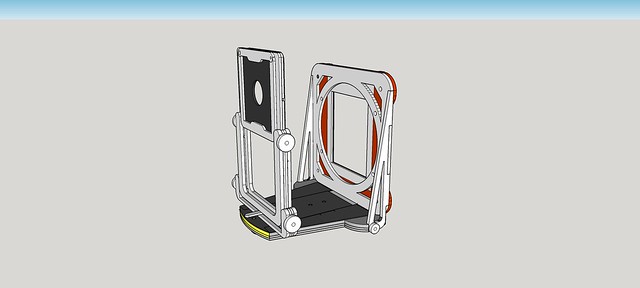

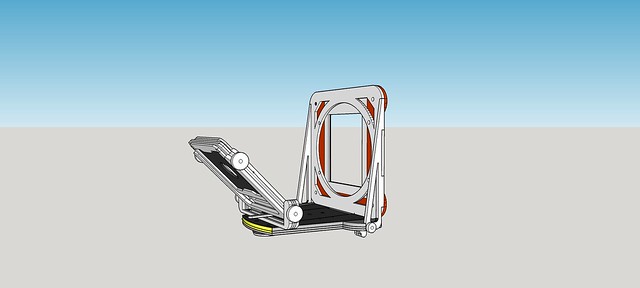

Too "custom"? ;0) First assembly

First assembly First assembly

First assembly First assembly

First assembly First assembly - Telephoto

First assembly - Telephoto First assembly - Wide Angle

First assembly - Wide Angle First assembly

First assembly First assembly - DIsassembled

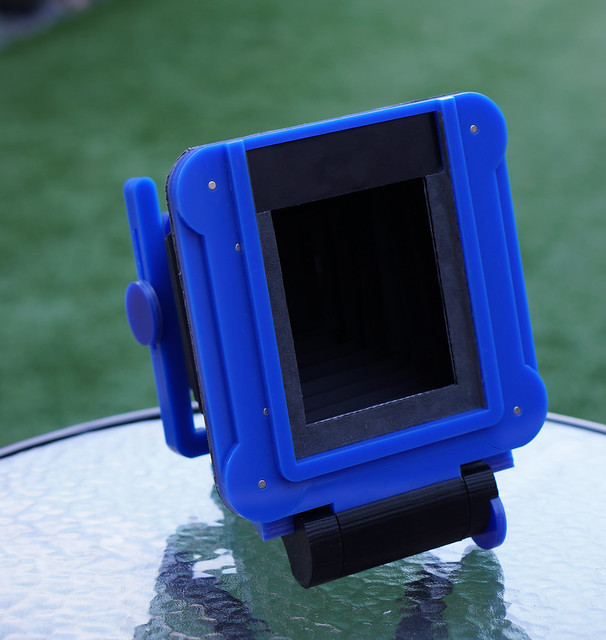

First assembly - DIsassembled First assembly - Rear - Landscape

First assembly - Rear - Landscape First assembly - Rear - Portrait

First assembly - Rear - Portrait

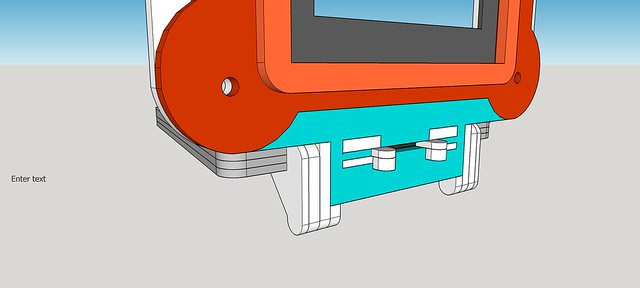

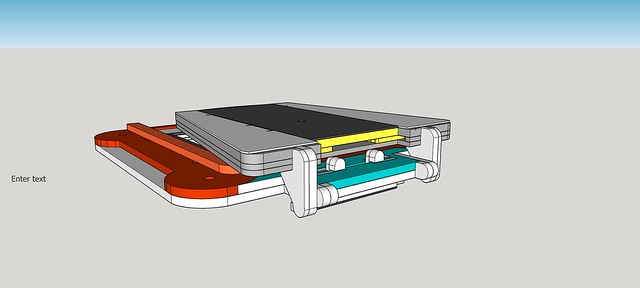

New Hinge and Spring Clip - Open

New Hinge and Spring Clip - Open New Hinge and Spring Clip - Closed

New Hinge and Spring Clip - Closed

All

All  Technical Standard Overview

Technical Standard Overview Technical Standard - 75mm Rise

Technical Standard - 75mm Rise Technical Standard - 25mm Fall

Technical Standard - 25mm Fall Technical Standard - 45mm Front Tilt

Technical Standard - 45mm Front Tilt Technical Standard - 45mm Rear Tilt

Technical Standard - 45mm Rear Tilt Technical Standard - 55mm Right Shift

Technical Standard - 55mm Right Shift Technical Standard - 45 Degree Right Swing

Technical Standard - 45 Degree Right Swing