- Messages

- 609

- Name

- Barry

- Edit My Images

- Yes

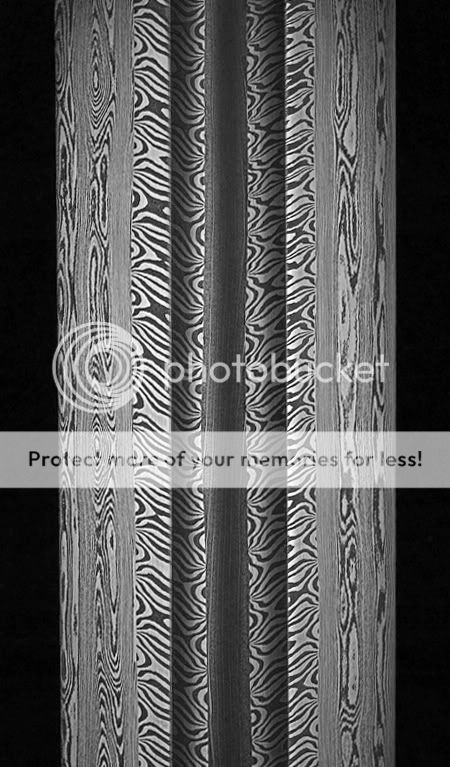

this is the blade close up of one of my Damascus knife blades...you can see the unusual metal structure from the forging...i only wish I could afford to buy more..

http://i35.photobucket.com/albums/d174/kneetrembler67/Knives/DSCF7032.jpg

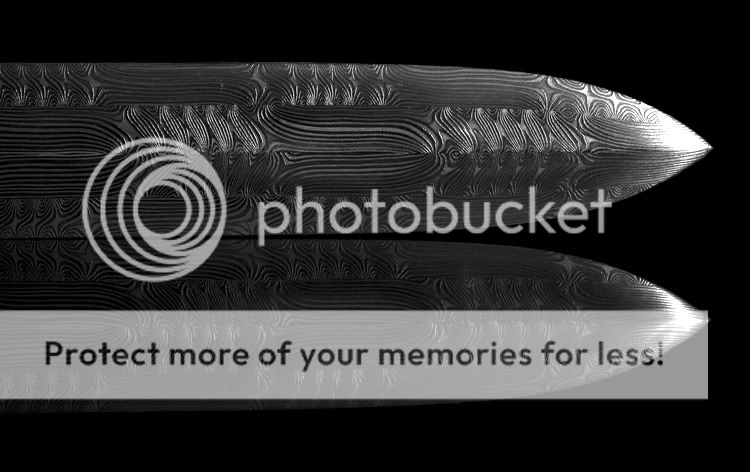

And from a distance

http://i35.photobucket.com/albums/d174/kneetrembler67/Knives/DSCF7160.jpg

Staff Edit : Images changed to clickable links. Pictures must not exceed current forum limits as per the rules. Please feel free to replace this with a fresh/resized image and remove this text

http://i35.photobucket.com/albums/d174/kneetrembler67/Knives/DSCF7032.jpg

And from a distance

http://i35.photobucket.com/albums/d174/kneetrembler67/Knives/DSCF7160.jpg

Staff Edit : Images changed to clickable links. Pictures must not exceed current forum limits as per the rules. Please feel free to replace this with a fresh/resized image and remove this text

Last edited by a moderator: