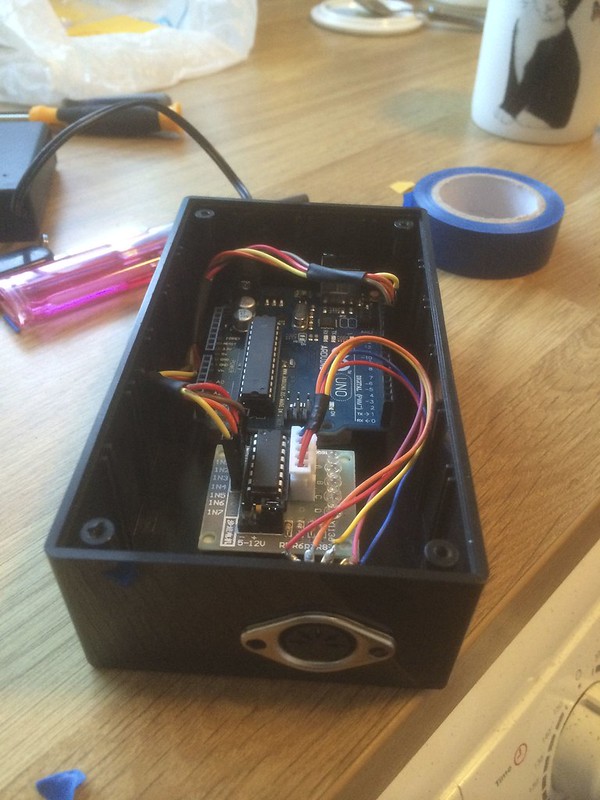

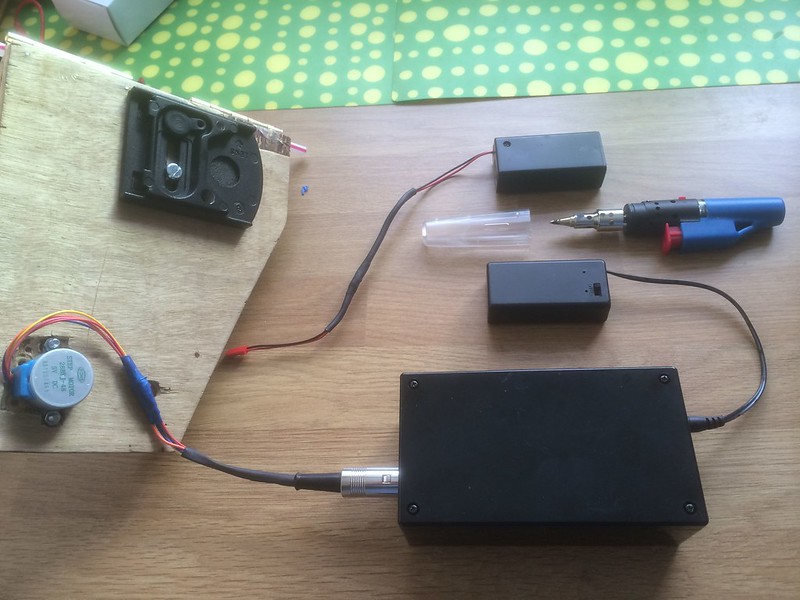

Now for the fun part, programming the Arduino. I spent about 2 weeks researching this and still not sure how or what I did but I got it working perfectly. The motor has to turn at 4RPM to make the drive bolt on the brass rod turn at 1RPM through the gears.

It is quite easy to upload a program to the Arduino using the usb cable supplied with it.

To do so you need the Arduino IDE software readily available on the Arduino site. At first I just tinkered with various programs that I downloaded from the web. There are loads out there with a lot of tutorials.

I just wanted to get the hang of using and changing the motor parameters. Arduino programs are known as sketches.

Next I downloaded quite a few motor sketches and then tried to change them for my requirements.

I eventually found one, which after changing a few things in the sketch, worked perfectly.

From what I have learned about the programming and the bits to change in the sketch I found that the parts to change in the sketch just didn't make sense and the motor wouldn't turn at the required speed. I eventually got there by trial and error and it works perfect at the required speeds.

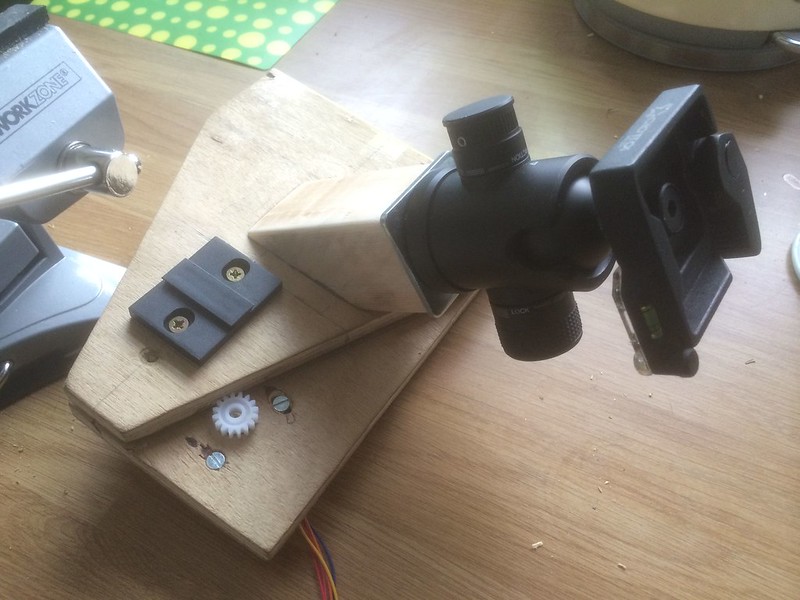

I then tested the motor and gears attached to the tracker using the stop watch on my laptop and the larger gear turns at exactly 1RPM.

I have this code available if anyone requires it.