- Messages

- 10,055

- Name

- Steve

- Edit My Images

- No

I blame @Carl Hall for this but we were talking over the weekend about my next project and came up with 2. Firstly, the dark cloth hoody which is basically a standard hoody with a longer/larger hood which can be pulled over your head and around the ground glass for focusing then dropped back down afterwoods so you look a little less like Superman in Wellies ;0) I've already spoken to my sweat shop about this (my mum) and am putting together something that can be attached to an existing hoody so you can wear it with your own clothes rather than making a complete new piece of clothing. I actually think this could be pretty good and Carl's even offered to buy the first so I'll hold you to that bud!

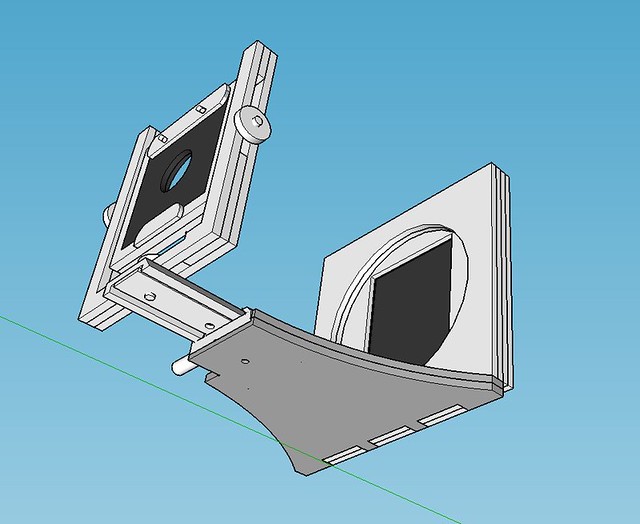

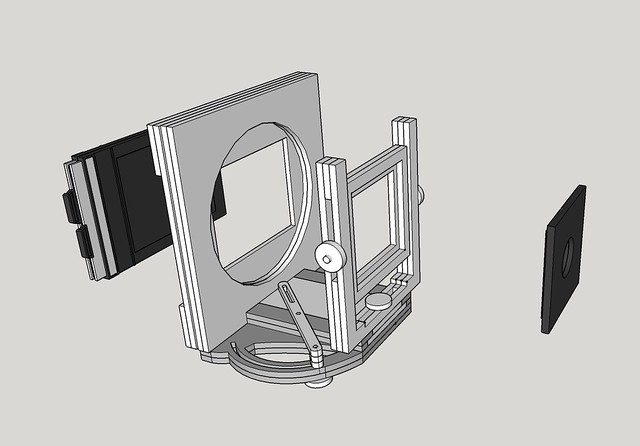

The second crazy idea was making a 4x5 field camera entirely out of lasercut acrylic sheet. In my head I'm going to make one of out translucent acrylic for added crazy value but initially I'll make it opaque;

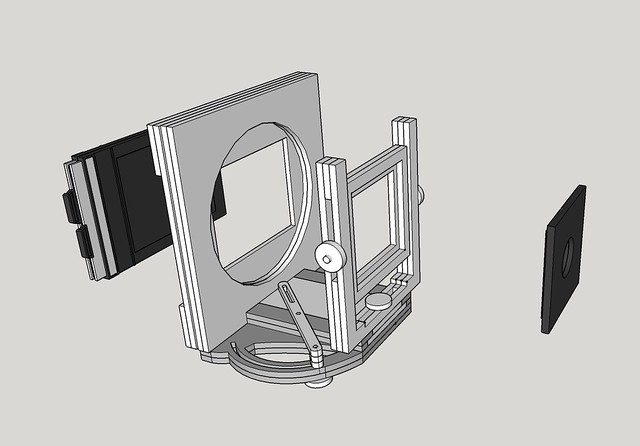

Shortest Focal Length (around 120mm with current design)

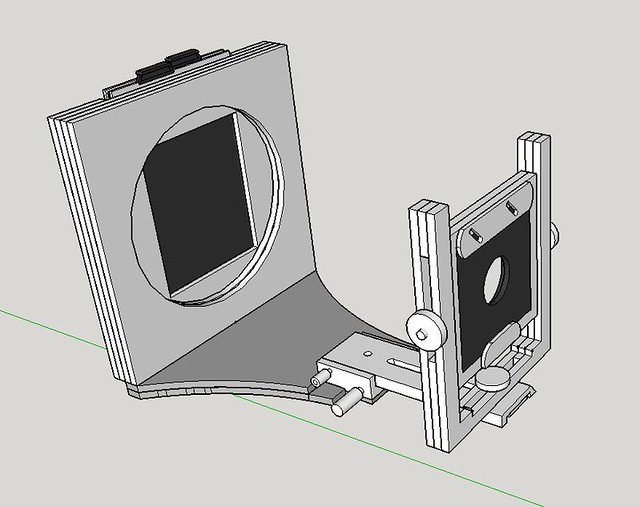

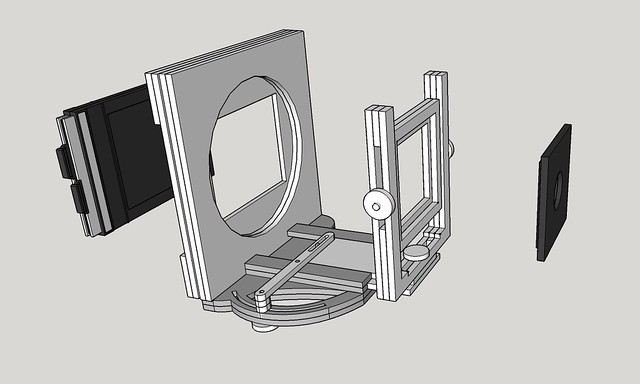

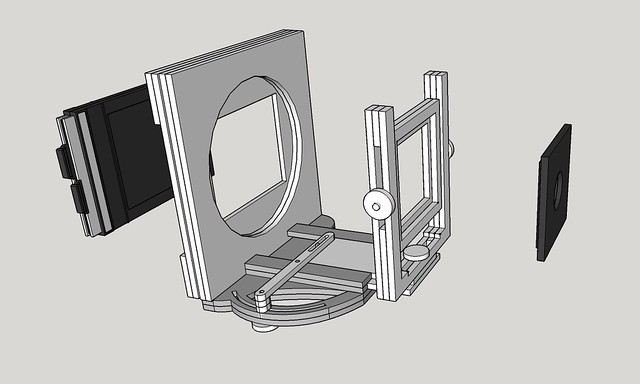

Medium Focal Length

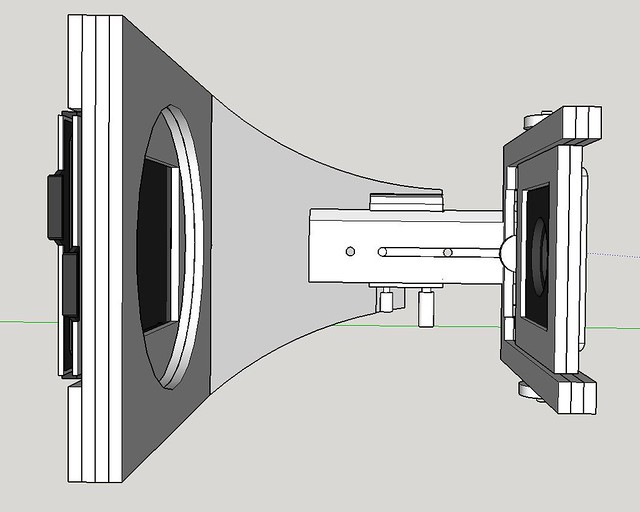

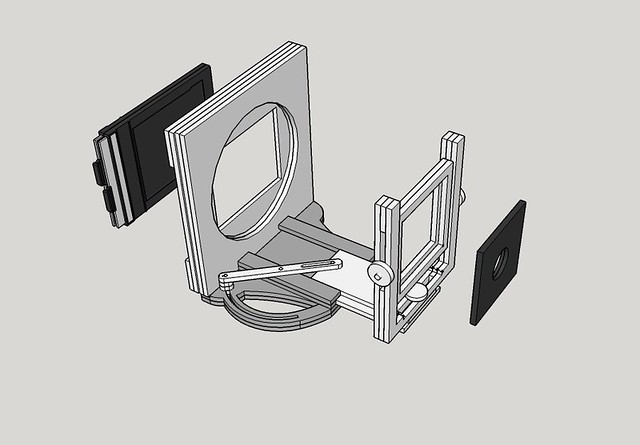

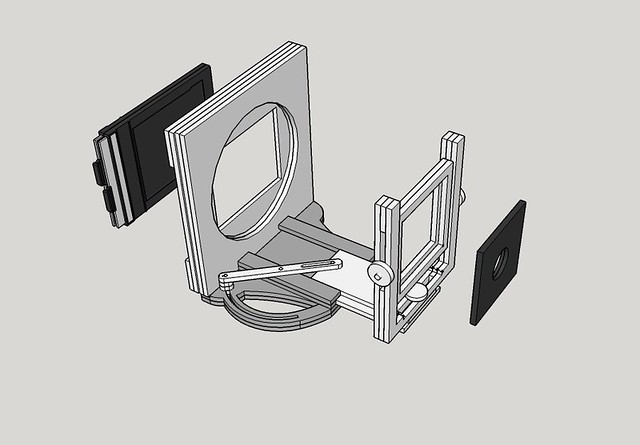

Longest Focal Length (around 220mm with current design)

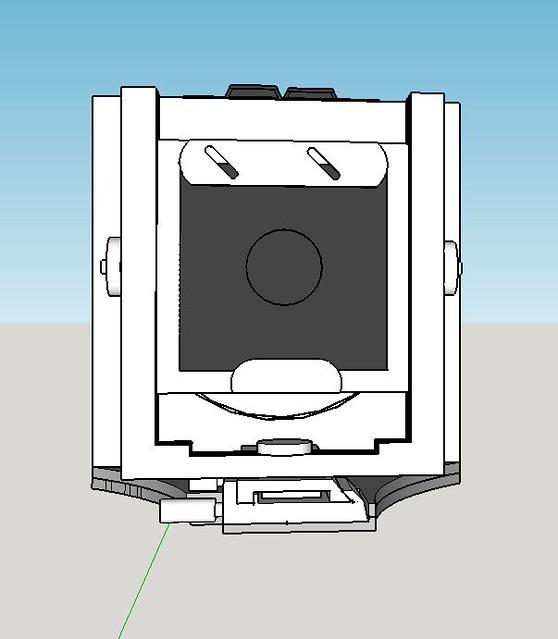

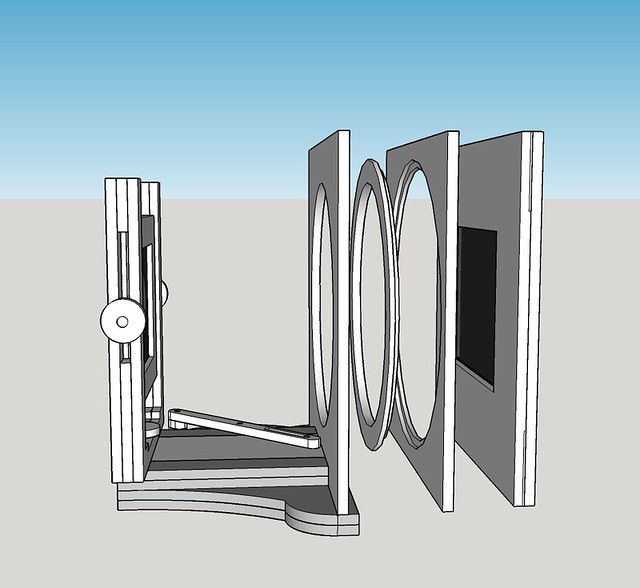

The back rotates to allow portrait/landscape shooting.

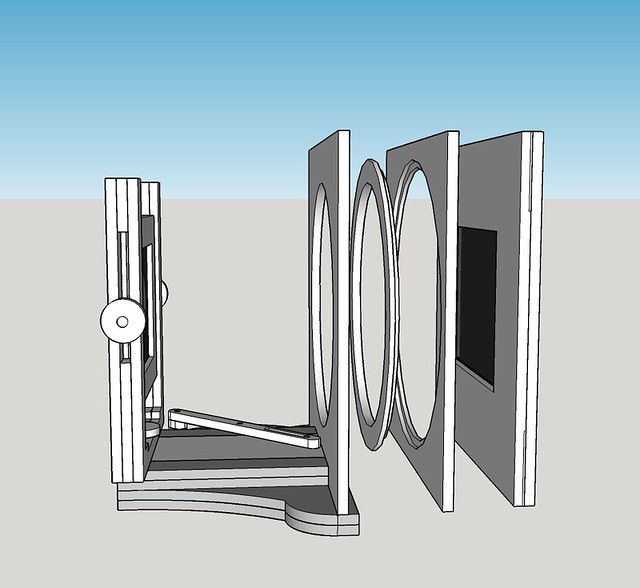

Exploded view of revolving back components;

I'm using the same friction fit for the DDS that I used on the Polaroid 110 conversion which means there's no need for additional brackets/clamps to keep it simple. Fully extended, the whole camera is 240mm long and 225mm high so quite compact. The rear standard slots through the base so is fixed with no movements for simplicity and the front standard is removed by unscrewing the central bolt in its' base so the camera can be separated for packing. I haven't split the parts out into a flat layout to work out how much acrylic will be needed yet but I'm hoping it will be kept down to a small area to keep the cost down. I'll get in touch with my friend with the laser cutter to get some costs.

The second crazy idea was making a 4x5 field camera entirely out of lasercut acrylic sheet. In my head I'm going to make one of out translucent acrylic for added crazy value but initially I'll make it opaque;

Shortest Focal Length (around 120mm with current design)

Medium Focal Length

Longest Focal Length (around 220mm with current design)

The back rotates to allow portrait/landscape shooting.

Exploded view of revolving back components;

I'm using the same friction fit for the DDS that I used on the Polaroid 110 conversion which means there's no need for additional brackets/clamps to keep it simple. Fully extended, the whole camera is 240mm long and 225mm high so quite compact. The rear standard slots through the base so is fixed with no movements for simplicity and the front standard is removed by unscrewing the central bolt in its' base so the camera can be separated for packing. I haven't split the parts out into a flat layout to work out how much acrylic will be needed yet but I'm hoping it will be kept down to a small area to keep the cost down. I'll get in touch with my friend with the laser cutter to get some costs.

Last edited: