Asha

Blithering Idiot

- Messages

- 11,274

- Name

- Asha

- Edit My Images

- Yes

Today I’m in my darkroom ….. First time in ages!

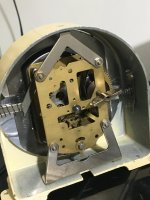

I’ve dug out my old Smiths clock ( I just love these old methods as opposed to modern tech) .

Anyway it’s not so happy with itself in so far as running slow at times , like really struggling to turn for a few seconds then it regains its rythme for a while until it struggled against another stubborn spot.

I’ve tried cycling it a number of times and it was showing some improvement but then following a pause, it’s problem has returned.

I’ve removed the back and I have some very fine ( sewing machine) oil , however I am no expert with clock workings so I’m asking you lot for advice.

Does it need lubricating and if possible to do it myself, what bit do I lubricate ?

I’ve dug out my old Smiths clock ( I just love these old methods as opposed to modern tech) .

Anyway it’s not so happy with itself in so far as running slow at times , like really struggling to turn for a few seconds then it regains its rythme for a while until it struggled against another stubborn spot.

I’ve tried cycling it a number of times and it was showing some improvement but then following a pause, it’s problem has returned.

I’ve removed the back and I have some very fine ( sewing machine) oil , however I am no expert with clock workings so I’m asking you lot for advice.

Does it need lubricating and if possible to do it myself, what bit do I lubricate ?