- Messages

- 8,479

- Name

- Trevor

- Edit My Images

- No

This project

'Kin Ell..

'Kin Ell..

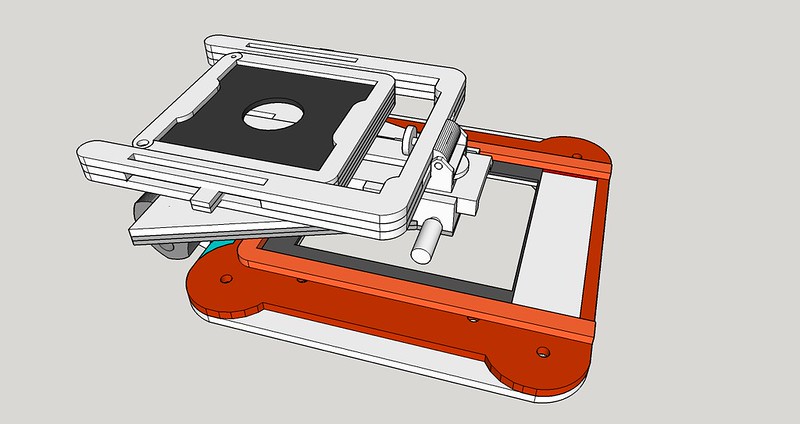

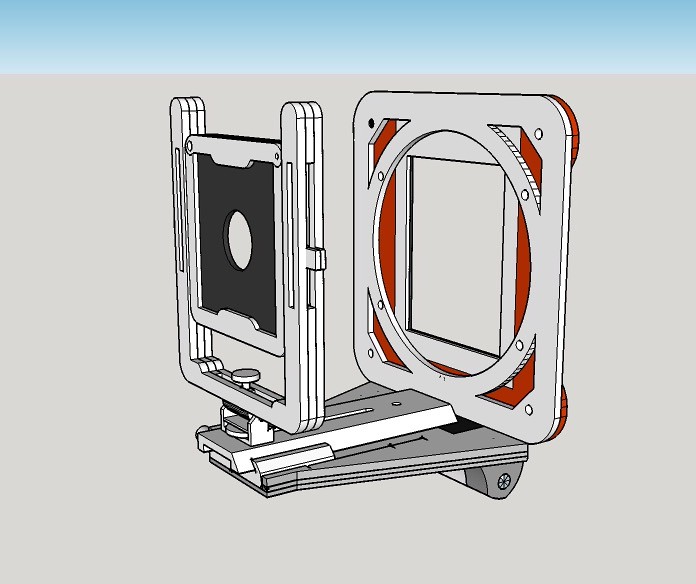

Working on the folding front standard to add independent movements. by Steve Lloyd, on Flickr

Working on the folding front standard to add independent movements. by Steve Lloyd, on Flickr Working on the folding front standard to add independent movements. by Steve Lloyd, on Flickr

Working on the folding front standard to add independent movements. by Steve Lloyd, on Flickr Working on the folding front standard to add independent movements. by Steve Lloyd, on Flickr

Working on the folding front standard to add independent movements. by Steve Lloyd, on Flickr Working on the folding front standard to add independent movements. by Steve Lloyd, on Flickr

Working on the folding front standard to add independent movements. by Steve Lloyd, on Flickr

Haven't been around much recently but this looks like it's progressing really well!

If you are comfortable sharing the 3D files, I'd love to try making one out of aluminium sheet! I fully understand if you'd rather not share them however

I think this project wormed its way into my dreams - last night I dreamt I was assembling a 4x5 camera out of parts, but my bellows were all saggy, like a stretchy old jumper.

If you are comfortable sharing the 3D files, I'd love to try making one out of aluminium sheet! I fully understand if you'd rather not share them however

I'd be happy to assemble myself, but others might not be. Often with these things, they're offered in various stages, such as...

Basic kit of fabricated parts, do the gluing and sort the hardware and fixings out yourself.

Fabricated parts plus hardware and fixings.

Glued bits assembled, with or without hardware.

Fully assembled.

my bellows were all saggy, like a stretchy old jumper.

I'm suspicious of my subconscious, if I'm honest.I've had that dream.

I would like to see the files too.

Rob - have you got the X-Carve router?

Steve.

I'd be happy to assemble myself, but others might not be. Often with these things, they're offered in various stages, such as...

Basic kit of fabricated parts, do the gluing and sort the hardware and fixings out yourself.

Fabricated parts plus hardware and fixings.

Glued bits assembled, with or without hardware.

Fully assembled.

I think this project wormed its way into my dreams - last night I dreamt I was assembling a 4x5 camera out of parts, but my bellows were all saggy, like a stretchy old jumper.

For the un-assembled versions, doesn't that mean idiot-proof instructions? Think back to your first Ikea assembly...

That's a bag bellows isn't it?

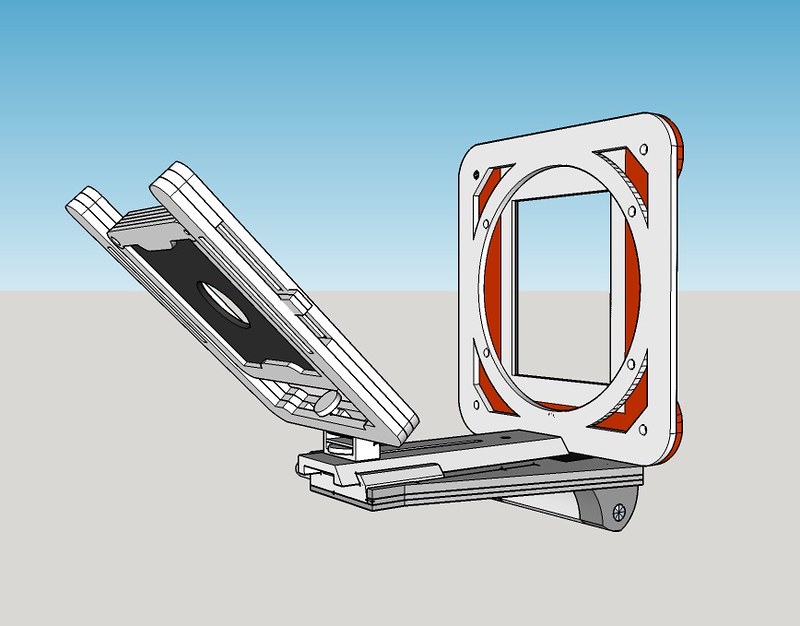

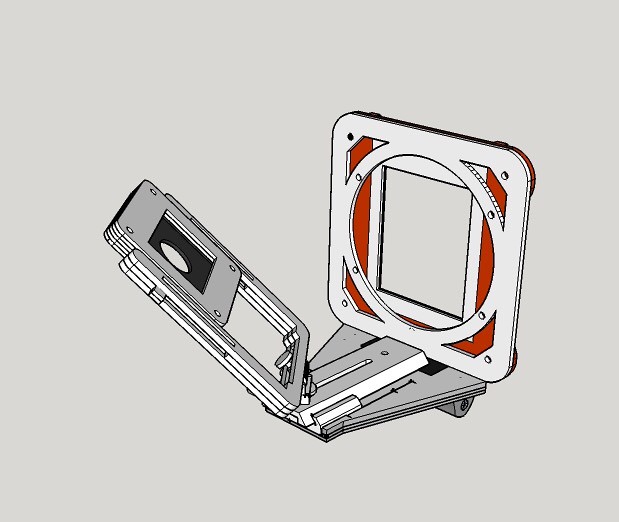

First assembly, sneak preview! by Steve Lloyd, on Flickr

First assembly, sneak preview! by Steve Lloyd, on Flickr First assembly, sneak preview! by Steve Lloyd, on Flickr

First assembly, sneak preview! by Steve Lloyd, on Flickr First assembly, sneak preview! by Steve Lloyd, on Flickr

First assembly, sneak preview! by Steve Lloyd, on Flickr First assembly, sneak preview! by Steve Lloyd, on Flickr

First assembly, sneak preview! by Steve Lloyd, on Flickrhttp://www.toolstation.com/shop/p10128?searchstr=tap and die will cover your tap and die needs and would probably be cheaper than postage both ways as well as being available next time you need one.

Looking good so far! Is the interior going to be lined or painted to stop/reduce internal reflection?

http://www.toolstation.com/shop/p10128?searchstr=tap and die will cover your tap and die needs and would probably be cheaper than postage both ways as well as being available next time you need one.

Looking good so far! Is the interior going to be lined or painted to stop/reduce internal reflection?

Looking and sounding really top notch Steve!

Thanks for the link. I was just asking on the off-chance to save me buying a full set but like you say, at that price it's a no-brainer.

A set is definitely a good idea. If you only have an M5 tap, there's a risk of designing everything to use that size.

The small T-type tap wrench in the linked set will have poor purchase on tougher materials and/or larger threads. They have their place for smaller sizes and softer materials, but you really need the longer bar type that clamp onto the end of the tap as well. Also, a set that only has taper taps will limit you in a couple of ways: Can't make blind holes without having to make a lot of clearance when drilling, and the thread will narrow as you go in (so you need to go in deep enough with the non-tapered portion to suit the length of screw you want to use). And, although they can make the correct threadform all the way through when making a thru hole, they can end up not being long enough in some cases - on some taps, the shank is narrower than the tapping drill size, which is fine, but on others (the smaller ones), the shank is bigger, meaning the tap stops when the shank hits the surface of the material. A set with taper and finishing taps helps mitigate both of these issues.

Plenty of tap wrenches to be found here...

http://www.chronos.ltd.uk/acatalog/threading_accessories.html

Either get a set with the long tap wrench and buy a short one or a T-type, or get a long one separately. The 'traditional style' ones should be better to use (I have a quality one made by Presto tools, and it easily outclasses the ones you see in sets with the little sliding block in the middle - feels very solid and tightens well just with the hands). I also have the mini tap wrench there, and find that I always use it for the small taps rather than the T-type that came with the set (but I use a T-type at work and find that okay as well).

You also need tapping drills if you don't have the laser cutter making holes of the correct size to begin with (4.2mm for M5, etc). Depending on what you need and what you already have, it's potentially better value to get a set of 0.1mm increment drill bits instead of buying individual tapping drills. I have the 1-6mm HSS set from Chronos...

http://www.chronos.ltd.uk/acatalog/Engineering_Menu_Drill_Sets_177.html

...and they've been excellent (but currently out of stock). Sets up to 10mm are dearer, and it may be better to get those as individual drill bits (only 3 needed, for M8, M10 and M12, and you might not need them anyway). The little set of 1-6mm are very versatile - I use them loads.

I've been following this for months.

Just want to say, I never fail to be impressed, thanks Steve, you're entertaining and educating lots of us.