- Messages

- 10,055

- Name

- Steve

- Edit My Images

- No

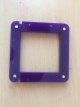

These are the two standards side by side. I'm happy with the size of the traditional standard (on screen anyway!) and it will fold into the body in the same way as the technical standard so I'm going to cut it this week. I'll also cut the technical standard so I can test them both out.

At the moment, the front plate of the bellows is a tight fit around the embedded Acrylic seal on the back of the standard so I don't need any additional fixings. I'll test how well it holds with the new standard too before deciding on having embedded magnets or not.

At the moment, the front plate of the bellows is a tight fit around the embedded Acrylic seal on the back of the standard so I don't need any additional fixings. I'll test how well it holds with the new standard too before deciding on having embedded magnets or not.