- Messages

- 10,055

- Name

- Steve

- Edit My Images

- No

That looks fantastic mate. Top work.

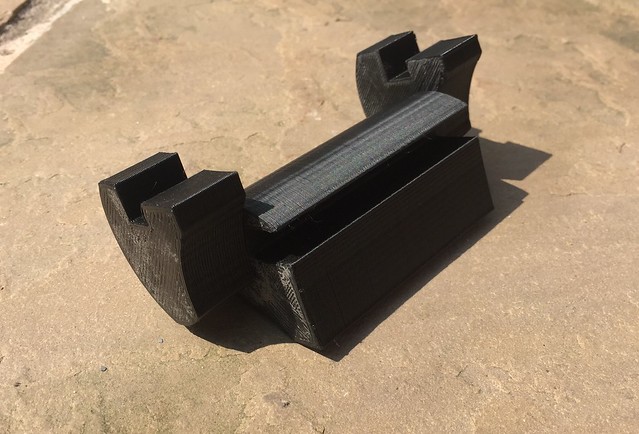

Thanks Andy. The bellows aren't attached yet so that's the next job, along with redesigning the lens board frame to be 3-6-3 layers rather than 6-6 so I can embed the thread better.

Uke

Uke

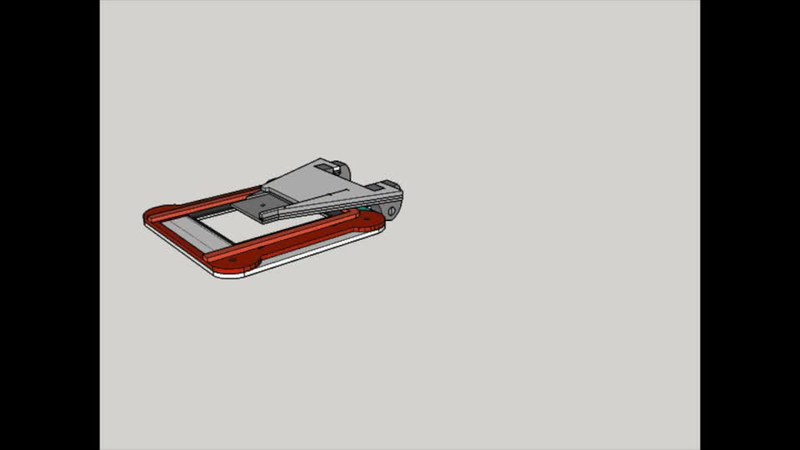

Rotating Hinge 4x5

Rotating Hinge 4x5